Design is a critical component of car manufacturing. A well-designed car not only looks great, but it also performs better on the road and provides a more enjoyable driving experience. When it comes to designing cars, few automakers have a reputation as strong as Volkswagen’s. From the iconic Beetle to today’s modern lineup, Volkswagen has consistently produced sleek, stylish vehicles that stand out on the road.

But how exactly does Volkswagen design its cars? In this post, we’ll take a closer look at the design process for Volkswagen cars, from initial conceptualization to final production.

Conceptualization

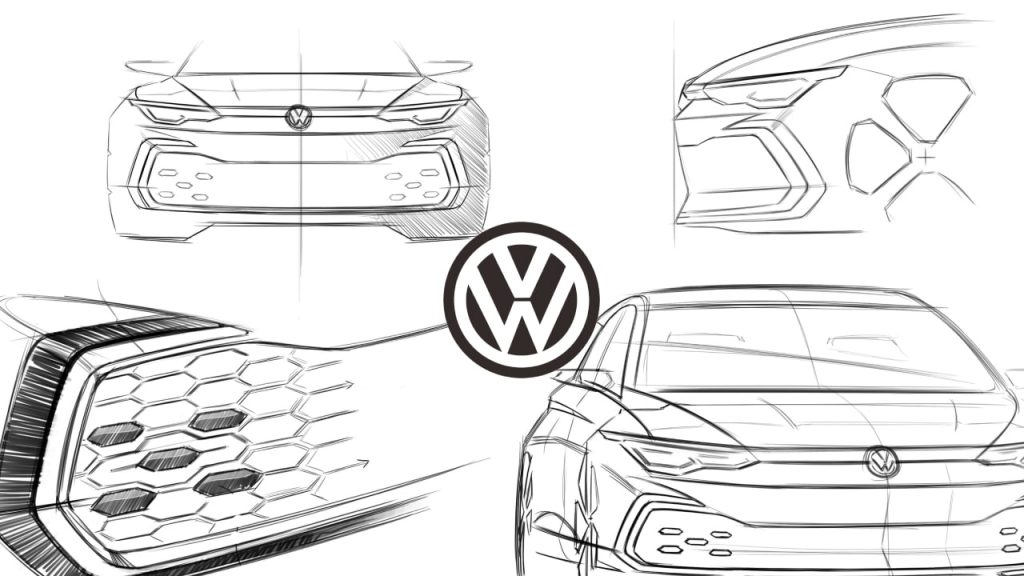

The first stage of designing any new car is conceptualization. This involves brainstorming ideas and sketching out rough designs on paper. At this stage, designers focus on creating something that meets both consumer needs and brand standards.

One of the ways Volkswagen accomplishes this is by using an “innovation matrix” during the brainstorming process. This matrix considers four key factors: customer benefit, technical feasibility, economic efficiency, and legal compliance. By taking these considerations into account from the very beginning of the design process, Volkswagen ensures that each new vehicle will meet customer needs while still being practical and profitable to produce.

Digital Design

Once designers have settled on some basic concepts for a new car model, they move on to digital design. Here they use computer technology and 3D modeling software to create virtual prototypes of their designs. This allows them to fine-tune details such as aerodynamics and aesthetics before moving on to physical prototyping.

One thing that sets Volkswagen apart in this stage is its use of augmented reality (AR) technology. AR allows designers to see what their virtual designs would look like in real-world environments, for example, how a new SUV might look parked in front of someone’s house or driving down a busy street. This helps designers get a better sense of how their designs will actually look in context once they hit the market.

Physical Prototyping

After refining their digital models through feedback from engineers and other stakeholders, designers move on to physical prototyping. This involves creating clay models of the car’s exterior and interior to test aerodynamics and aesthetics.

Volkswagen uses advanced milling machines to create these models with extreme precision, some models are accurate down to just one millimeter! Once created, these models are refined further through feedback from engineers who evaluate them for things like safety features and performance enhancements.

Finalizing the Design

With input from engineers and other stakeholders incorporated into the design through multiple rounds of refinement during conceptualization and physical prototyping stages; designers can now finalize the design by incorporating safety features such as airbags or crash-resistant frames into it alongside performance enhancements such as engines with higher horsepower ratings or improved fuel economy ratings.

This balance between form and function is crucial when it comes to designing cars – after all; no one wants a beautiful car that doesn’t perform well on the road!

Production

Finally, once all aspects of vehicle design have been finalized, including safety features like airbags or crash-resistant frames along with performance improvements like more powerful engines or increased fuel efficiency ratings. VW must translate these blueprints into production-ready specifications so that manufacturing teams can start building each new model precisely according to its intended specifications without errors or deviations from original designs due to misinterpretation or misunderstandings among workers responsible for assembling various vehicle components together during production line operations.

Quality control measures are also implemented throughout every step along VW’s manufacturing lines starting from the raw materials sourcing phase up until finished vehicles are released into marketplaces around the world ensuring each car meets rigorous quality standards set forth by the company management team overseeing the entire production chain globally across all regional markets where VW sells its vehicles worldwide today.

Conclusion:

In conclusion; designing cars isn’t easy – it requires creativity alongside technical know-how plus attention paid towards practical considerations such as customer needs alongside regulatory requirements which vary globally depending upon specific regions where companies sell vehicles worldwide including different rules governing emissions levels among others which must be taken into account when developing new models aimed at specific target markets around the world today.

Throughout every stage of designing new Volkswagen cars; innovation plays a central role in combining advanced technologies with traditional craftsmanship skills honed over decades producing high-quality products customers love year after year.

By balancing form with function while remaining true to the brand identity established over time; VW has managed to stay ahead curve in the competitive automotive marketplace offering consumers premium vehicles known equally well for their style alongside performance capabilities delivering exceptional value propositions relative to those offered by other automakers globally today!